This antenna is a directive one, useful for a short distance Point-to-Point link. It may be also used as a feeder for a Parabolic Dish or Grid. It is very cheap and quite easy to build, requiring just a piece of wire, an N socket and a metallic plate. The plate has a hole drilled in the middle to accommodate an N type socket. The wire is shaped as an ‘8’, but with squared angles and then soldered to the N socket. For this antenna the gain will be in the order of 10 to 12 dBi, with a beamwidth of around 60 degrees.

Parts list:

- one screw-on N-type female connector

- 30 cm of copper or brass wire of 2 mm of diameter

- a square metallic plate of at least 12.3x12.3 cm (aluminum is preferable)

Tools required:

- ruler

- pliers

- file for metal

- small rat-tail file

- cutter

- saw for metal

- soldering iron

- solder

- drill with a set of bits for metal (with a 1.5 cm diameter bit)

- vice or clamp

- hammer

- spanner or monkey wrench

Construction:

Straighten the wire using the vice.

Cut the metallic plate to have a square shape of 12.3x12.3 cm. To do this, you may use the saw, but we suggest to use a thin (0.8 to 1.5 mm) aluminum plate, which can be cut with a cutter.

Draw the correct dimensions on both sides of the plate with a marker. Carve the drawn lines with the cutter pressing firmly, helping yourself with the ruler. Do this a couple of times, on both sides of the plate. Bend the plate over the lines until it breaks.

The edges can be now very sharp. Be careful when handling the plate. Use the file to smooth the edges all around.

With a marker and a ruler, draw the diagonals on the metallic plate, finding its center. With a small diameter drill bit, make a hole at the center of the plate. Increase the diameter of the hole using bits with an increasing diameter.

The hole should fit exactly the N connector. Use the file if needed.

Now we want to shape the wire as an ‘8’, composed by two squares connected on one edge. The two squares have a side of 3.05 cm.

Bend the wire at 90 degrees in his central point using the vice and the hammer.

With a marker, draw a line at 3.05 cm from the edge, and bend the wire at 90 degrees in this point with the vice and the hammer as before, but in the opposite direction (it should look like a ‘Z’).

Draw another line at 3.05 cm from this new edge, and bend the wire at 90 degrees in this point, in the same direction as before.

Draw now a line at 3.05 cm from the last edge, and a second line after 2.3 cm from the first one. Bend the wire at 90 degrees in the second line, in a direction orthogonal to the plane containing the wire, as shown.

Bend the wire at 90 degrees in the first line drawn in the previous step in order to “close” the square, as shown. The wire at this point should now look like this:

Shape the second half of the wire to obtain another square, repeating the procedure described in steps from 6 to 9. The result should be this one:

With the saw and the rat-tail file make two small, half-round shaped cuts in the connector’s nut at 60 degrees one from each other. The cuts should be on two contiguous edges of the nut, and should be large enough to fit half of the wire’s diameter. File also around the cuts. Be careful not to cut too deeply inside the nut: enough metal should remain to ensure its robustness.

Trim the two ends of the wire at a length of 1.5 cm.

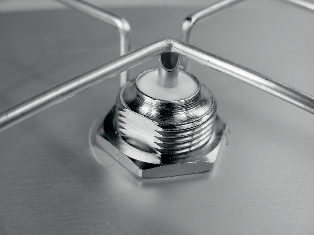

The wires should now fit in the nut’s cuts as shown.

Tin the ends of the wire for 0.5 cm. Tin around and inside the cuts of the nut with a small amount of solder, and then solder the wires to the nut.

Remove the exceeding solder with the file, so that the nut can be screwed correctly.

Insert the connector into the hole of the metallic plate and screw the nut with the wire soldered on it.

Rotate the nut so that the diagonals of the two wire squares are parallel to the side of the metallic plate. Then screw it firmly with the spanner.

We now want to solder the central pin of the connector to the center of the shaped wire. You may have either a short or long type of N connector, as shown. The central pin of the long type may be soldered directly on the shaped wire, while the short type of connector needs ad additional short piece of straight wire to be soldered into the central pin. We are going to use the long type of N connector.

Tin the central pin of the connector and solder the center of the shaped wire to it.

The antenna is now completed. If you have a Spectrum Analyzer with Tracking Generator and a Directional Coupler, you can check the curve of the reflected power of the antenna. The picture below shows the display of the Spectrum Analyzer.

Radio Laboratory Handbook

Marco Zennaro

Carlo Fonda